|

by Seth Shulman

"I'm going to pour gasoline on

that motor and set it on fire once we get our new four-stroke engine

installed."

Elwood Norris, inventor, promoter, and full-throttle enthusiast about the

dream of building a personal flying machine, is joking about the

temperamental Italian two-stroke engine that powers a contraption he

refers to as his baby. Right now his baby won't fly. Experimental

aviation, circa 2002, is grounded by a faulty carburetor. The machine,

officially known as the AirScooter, sits on the edge of a roughly mown hay

field near Newport News, Virginia, somewhat ungainly on its big red rubber

pontoons. Norris' aircraft is an open-cockpit, twin-rotor ultralight

helicopter that, today, is scheduled to make one of its first

demonstration flights, orchestrated for this magazine. The glitch is

embarrassing, but Norris is not really fazed. The AirScooter will fly, he

promises. And, indeed, before the demo is over it will display its

potential—it's the closest thing yet to a sturdy, mass-marketable flying

machine for casual amateur use.

How can there be, a hundred years after Kitty Hawk, any talk about a dream

of personal flight? Didn't Otto Lilienthal, the Wright brothers, Glenn

Curtiss, Charles Lindbergh, Amelia Earhart, William Lear, and all the

other aviation pioneers put that dream to rest? The answer is that the

AirScooter and its ilk, a class of flying machines that dates back many

decades, represent a kind of suburban sequel to the Wright stuff, in which

the science of aviation is brought home, domesticated, made, as Chrysler

described its minivan, "garageable." The idea gained momentum in the

optimistic era after World War II, and remains appealing because it

promises, as the car once promised, personal power and adventure for the

ordinary man or woman. With the car now often gridlocked on roads to and

from suburbia, a machine that can fly above the car suggests freedom from

the tyranny of two-dimensional blacktop. It is—the grand vision—a fantasy,

but enormously attractive.

The airplane never really promised this. The development of the

helicopter, though, seemed to. As Edwin Teale speculated in this magazine

almost 70 years ago, four years before the first single-rotor Sikorsky

helicopter flew, "Office buildings could be capped with honeycomb cells

holding the helicopters of the workers, each craft dropping into its

compartment in the morning and rising straight up from it at night; aerial

shuttle lines could link centers of population with airports and suburbs.

These are not fantastic visions. . . . As these words are being written, a

cable from England tells of dramatic progress."

To really deliver on the dream, then, the personal flying machine cannot

be dependent on an airstrip or lake—as even the smallest ultralight plane

is—but must take off and land vertically. It must be as easy to operate as

an SUV, which no conventional helicopter is. And it must be cheap enough

for the middle class car owner—the standard American dreamer—to buy and

maintain, far cheaper than a Cessna or little Bell chopper.

Homebuilt helicopters and gyrocopters

(machines with unpowered overhead rotors) already exist, of course, constituting

a finicky subset of machines flown by mechanically inclined enthusiasts; the

Popular Rotorcraft Association has chapters in 30 states and five other

countries. But such devices remain either too difficult to fly or too

time-consuming to maintain to be suitable for mass-production and wide

acceptance.

This is where Norris enters. After developing a string of inventions—including a

linear-tracking phonograph, a forerunner of the sonogram, and one of the first

prototypes for cellphone earpieces—Norris, a small-plane pilot, turned to the

personal flying machine because, he says, "Everybody I have met seems to have

this dream to get off the ground and defy gravity." Norris claims his Henderson,

Nevada-based AirScooter Corp. will have its first production machines on the

market by early 2003, at a likely price of $25,000 to $50,000—somewhere between

the cost of a well-equipped Ford Explorer and a Lincoln Navigator. And, he

promises, you can learn to fly it in an hour.

What will you get for the money? No leather seats or plush interior, that's for

sure. Norris' prototype AirScooter has a fabric mesh sling seat, the kind you

might find on a lawn chair, and handlebars that look like they've been lifted

from a mountain bike because they have been lifted from a mountain bike. It has

a vertically mounted engine topped by two sets of spindly coaxial helicopter

blades—one above the other on two concentric driveshafts—that rotate in opposite

directions. And then there are the pontoons, which are specially manufactured by

a company that makes whitewater rafts.

If the AirScooter seems stripped down to bare essentials, there's a reason. Its

creators wanted it to weigh less than 254 pounds so it could duck most Federal

Aviation Administration regulations by qualifying as an ultralight craft. Most

important to Norris and his team, this designation means that you won't need a

pilot's license to fly the AirScooter (although other ultralight rules do put

limits on speed, altitude, and the like). The machine was built with attention

to every ounce: Few of its parts exceed a pound and a half. There is hardly any

instrumentation. The rotor blades are a mere 14 feet long. At a remarkable 247

pounds, the AirScooter is lighter than many motorcycles—not including its two

30-pound pontoons, which get by courtesy of an FAA safety rule. Think, then, not

of a flying Ford Explorer but of an airborne ATV.

To go left or right, you turn the handlebars to the side; to move forward or

back, you push the handlebar assembly out or pull it toward you. These

instinctive motions adjust the position of the yaw paddles or the rotors (see

diagram, page 52). To go up or down, you twist the handlebar throttle with your

right hand—just as you would to accelerate on a motorcycle. The throttle simply

increases the rpm of the blades above your head to lift the craft higher in the

air. That's it. Pitch, yaw, and roll, all neatly taken care of. No foot pedals

or fancy dials. None of the five separate hand and foot controls you'd find in

the cockpit of a conventional helicopter.

Critical to the AirScooter's potential,

however, is the part not yet demonstrated: the new engine. The main problem with

most personal aircraft to date is that to minimize weight they employ two-stroke

engines, which are noisy, temperamental, highly polluting, and have a perilous

tendency to seize up. The 65-horsepower four-stroke Norris is having built

weighs only 80 pounds, but it is, he says, quiet, reliable, low-maintenance,

cleaner, and most of all, safer. It's made of aluminum and magnesium alloy and

protected from melting at high temperatures by an inner ceramic coating. In

addition, it's continuously lubricated by a pressurized distribution tube from a

separate oil tank, so it should run smoothly not only when the AirScooter is

horizontal but also during twists, turns, and other maneuvers. Norris knows that

the four-stroke is the key to delivering on the AirScooter's promise. Though it

added greatly to the cost (he's sunk several million dollars into the AirScooter

project so far), he founded a second company, AeroTwin Motor Corp., solely to

develop the four-stroke. (As this issue went to press, testing remained

imminent. Norris promised a tour de force.)

Even without the new engine, the machine simply feels good to sit in. And here

in Newport News, I've been promised a chance to fly it, tethered for safety. I

love aviation but I'm no pilot, so the notion of learning to operate a

vertical-takeoff flying machine in less time than it takes to figure out how to

set up a new PC is terrifically appealing. All of which means, of course, that

I'm a target customer for the AirScooter. For now, though, I just sit. The crew

can't get the peevish two-stroke to cooperate.

"Personal flight has always been my dream," says veteran inventor Craig vet- ter.

"The time has arrived." Vetter, of Carmel, California, is best known for

pioneering motorcycle designs like the celebrated Triumph Hurricane, but for the

past few years he's been threatening to launch a contest to build a viable

personal flying machine. Vetter hasn't found sponsors willing to put up the

$100,000 prize money he thinks he needs to draw major talent, but the idea is

not empty posturing: In the 1980s, Vetter sponsored a fuel economy contest that

showcased an array of prototype vehicles that could achieve almost 500 miles per

gallon in real highway conditions. The proposed rules for the new contest set

out Vetter's version of the dream: to build a vehicle that can fly "low and slow

. . . so it won't hurt too much if we crashed. . . . This is a contest to reward

mastery of airspace from the surface to 10 feet up." In what we might call

personal airspace, flying machines would cruise over or around obstacles and

stick to roads only in bad weather. In sun, they would scoot over the open

fields.

A handful of inventors could be

contenders if Vetter jumpstarts his contest, most of them taking advantage

of recent advances in lightweight composite materials and computer-aided

design. Along with Norris, former Navy combat pilot Michael Moshier leads

the pack. Mosh-ier's brashly conceived SoloTrek XFV (short for

Exo-Skeletor Flying Vehicle) has made dozens of short, tethered flights at

the Sunnyvale, California-based headquarters of his company Millennium

Jet. (This magazine described the SoloTrek last October.) If the

AirScooter is like an ultralight airborne ATV, Mosh-ier's machine—which is

supposed to have a range of 150 miles and a top speed of 80 mph—resembles

a strap-on, flying, high-performance superbike.

Moshier says his preoccupation with personal flight began when he saw the

U.S. Army-funded rocket pack that was featured in the 1965 James Bond film

Thunderball. The device, a backpack powered by rocket fuel, was real and

powerful, but terribly impractical—it ran out of fuel in about 20 seconds.

Today's SoloTrek has a 120-horsepower engine; two ducted, turbine-like

fans are positioned on either side of the pilot and spin in opposite

directions. A joystick in each of the pilot's hands communicates with a

computerized stability system: One controls speed, the other steers.

Because it's compact and has no exposed blades, the SoloTrek could allow

users to land in cramped spaces. But since the housed rotors sit side by

side, rather than on top of one another, the machine is potentially less

stable than the AirScooter: If the flaps on the SoloTrek's two fans get

out of sync, the machine could become unbalanced.

At 500 pounds, the SoloTrek doesn't meet the FAA's ultralight designation,

so you'd need a pilot's license to fly it. If you could afford to buy it,

that is: The complex avionics could push its price tag well past $100,000.

For now, Moshier envisions soldiers, not civilians, strapping on his rig.

Despite millions in Pentagon funding, money has been a chronic problem,

but Moshier says he devotes "150 percent of his time" to his invention.

Moshier's devotion pales beside that of maverick inventor Paul Moller.

Moller's M400 Skycar (which this magazine covered in March 2000) features

four horizontally mounted ducted fans, each powered by two Wankel-style

rotary engines, that together produce 720 horsepower. Moller intends his

Skycar to take off like a helicopter, fly much the way a car is driven,

and navigate on autopilot using the satellite-based Global Positioning

System: Clearly, he's reaching for the full realization of the personal

flying machine. He intends to deliver a working version of the sort of

craft depicted in films like The Fifth Element, in which urban flyers that

resemble old, round-edge Chevy Caprices zip about on invisible aerial

roadways. Problem is, though Moller claims his Skycar made a few-seconds

hop last year, no one outside his Davis, California-based company has yet

to witness the feat. The project has sapped his energies and at least $200

million of his and his investors' fortunes for some 40 years. He hasn't

lost faith. "We've had our dark days," he says. "But I know in my heart

that this technology is coming."

The helicopter may have been

the genesis of the idea of personal flight, but it also dashed hopes when,

after being perfected in 1943 by Igor Sikorsky, it proved far harder than

an airplane to fly. The dominant design employed by the big names in

commercial helicopters—Sikorsky, Bell, and Hughes—employ the so-called

single main torque system. The natural tendency in a single-overhead-rotor

craft is for the body to spin in the opposite direction as the rotor. The

small rear rotor was added to counteract that effect and keep the

helicopter steady. But the inherent instability of this system means that

even accomplished pilots find conventional helicopters hard to fly:

Control requires constant corrections, deft hand-foot coordination, and

intense concentration. Further, helicopters are complicated contraptions,

with blades that must change pitch as the pilot steers (as AirScooter test

pilot Jack Nolan puts it, "The blades fly the helicopter"). And

complicated contraptions are, of course, expensive.

The solution is a dual rotor system—with two equal rotors spinning in

opposite directions—to counteract the gyroscopic torque and yield a net

torque of zero. That eliminates the need for a tail rotor; as a result,

the controls can be vastly simplified. The rotors themselves can be

simplified, too, because their pitch can be fixed. With that

design—adopted by Norris and others—the pilot can simply increase the rpm

of the blades to go higher, or shift the weight of the aircraft to change

the rotors' attitude and to steer.

Consider the wee Gen H-4, brainchild of little-known Japanese inventor Gen

Yanagisawa, which weighs a mere 155 pounds, employs four 10-horsepower

125cc engines, and sells for around $29,900 as a build-it-yourself kit. It

reportedly can cruise at up to 55 mph for 30 minutes on a 21/2-gallon tank

of gas. Why wouldn't this machine trump Norris' AirScooter concept? Well,

the AirScooter looks positively rugged compared with the Gen H-4. Picture

hanging from two spinning rotors attached to what looks like a small

generator, in something that resembles an office chair with long spindly

legs. From a distance, an operator looks like he's literally flying by the

seat of his pants.

Not good enough, says Norris. "The AirScooter is going to be the first to

put all the pieces together in a workable flying machine that anyone can

buy off the shelf, and that is nearly maintenance-free and easy for anyone

to operate," he claims. "Heck," he says, "even people in wheelchairs will

be able to fly it."

Another offshoot of the dual counter-rotating

blade concept is a class of machine called a flying platform. This design

originated in the mid-1940s with engineer Charles Zimmerman's notion that the

instability of overhead rotors could be overcome if the operator stood above the

blades, controlling the machine with body movement; he called this his "flying

shoes" concept. Aviation pioneer Stanley Hiller made a version of the flying

platform that flew in 1955. Today's Hummingbird, made by the Israeli firm

Aero-Design & Development, is a typical current example. A little over 7 feet in

diameter, the machine resembles a giant tuna can; it contains two sets of

counter-rotating propeller blades and is powered by four tiny 22-horsepower

engines. The operator stands in a waist-high cage affair on top. The Hummingbird

can reportedly fly for about 30 minutes. AD&D says it hopes soon to sell the

machine as a kit for about $30,000. At 320 pounds, it's above the FAA's

ultralight limits, but build-it-yourself kits are exempted from these rules. The

Performance Aviation Manufacturing Group in Williamsburg, Virginia, meanwhile,

is already taking orders for a $50,500 kit for a similar flying platform design

called an Individual Lifting Vehicle. Company officials say it could be used by

ranchers to track cattle (a personal ranching machine, an aero-horse) or by

immigration officials to patrol borders.

And so it goes. There's no end to the iterations of this idea. Rafi Yoeli, an

Israeli engineer, ex-Boeing, has a 1,200-pound prototype in his Tel Aviv living

room of a machine called the CityHawk. A two-seater powered by twin gas engines

and a pair of 6-foot-wide internal fans (one in front of the other, on a machine

that looks a bit like a giant sandal), it relies on a computer-controlled system

of 300 flaps to translate the pilot's commands—or will, if CityHawk ever flies.

Now stop for a second: Imagine personal airspace, filling up with CityHawks,

AirScooters, SoloTreks, and Skycars. How likely is that? Not very likely

anywhere near the suburbs. Paul Takemoto, an FAA spokesperson, notes that the

fine print of Part 103, the regulations governing ultralight craft, requires

pilots to fly low enough that they can always see the ground, and much more

significantly, forbids flying through congested areas, in controlled airspace,

or even over open areas where lots of people might be congregating. Furthermore,

if commercial sales of personal flying machines were ever to really take off,

the FAA would no doubt leap to provide additional oversight. "We certainly

wouldn't hesitate to take another look at these regulations if we ever felt the

need to do so," Takemoto says, no doubt with considerable understatement.

Even Craig Vetter, who

envisions legions of "low and slow" craft breaking the blacktop gridlock,

acknowledges two critical safety issues. First, there's the problem of

whirling propellers like "swinging knife blades." Designers must build

these craft "so a child could come up and touch them anywhere before

takeoff and not get hurt," Vetter says. Second, there's what Vetter calls

the problem of the "dead man zone." Altitudes of 12 to 350 feet, where

many of these machines would operate, are high enough to kill a pilot in a

fall, too low for a conventional parachute to work. New escape gear will

be needed, Vetter says.

The first successfully marketed personal flying machine is unlikely to be

a flying car, zooming over Expeditions as they make their slow way into

the city. It's more likely to be an airborne ATV, scooting over empty

rural fields: a fun, reliable toy, no more expensive than a decent boat,

bringing the thrill of aviation to the man or woman who's tried the latest

jet-ski and wants to get some real air.

At the Virginia hay field, Art Phelps, one of AirScooter's lead engineers,

has retrofitted the stuttering two-stroke engine with a jury-rigged new

dual carburetor system. Meanwhile, AirScooter test pilot Nolan, a former

race car driver decked out in a black jumpsuit, conducts spot checks. He

examines the so-called teeter stops that keep the rotors from wobbling

until they are steadied by angular momentum when in motion. He tests the

rotors' belt drive. He finds a loose wire to the tacho-meter and works

with Phelps and a handy pocketknife to crimp it back into place.

Finally ready, Nolan hops into the sling seat, twists his right wrist on

the motorcycle-like throttle and, once the engine has finally coughed to

life, makes a graceful vertical takeoff. He loops around the open field

like a hummingbird—stopping in midair, hovering, rotating the craft at

will—then comfortably does a few laps at about 10 feet above the ground

before gracefully alighting on a little cement tarmac. The potential and

the allure of the AirScooter are unmistakable in this masterful

low-altitude flight. The thing flies—albeit noisily, another problem with

helicopters—and it looks incredibly easy to use. Nolan's test run is

followed by a round of ceremonial cannon fire from a small Civil War

replica a team member has brought to the site, as well as some hollering

and a hearty round of high-fives.

Nolan makes a number of short demo flights over the next several hours.

Then he wants to do a loop of the field to give the photographers a shot

of the AirScooter from below. But a pin shears off inside the engine at

startup, meaning another significant delay; the team will need to open the

engine again for repairs. As Phelps puts it, at this stage of development

it's virtually impossible to control for the "unk-unks" (unknown

unknowns). It will be nearly nightfall by the time they get the engine

fixed again. "Those unk-unks," Phelps says, "can really bite you."

Next day, a storm front descends, delivering thunderstorms, hail, and

near-gale-force winds. The tethered flight I'd been hoping to make is not

in the cards. I'm disappointed but, truth be told, not unhappy to wait for

the new four-stroke engine. Still, it was pure pleasure to watch Nolan

take the AirScooter up and around, precisely flying a helicopter with such

simple controls. The dream is alive here in this Virginia hay field.

Someday, one suspects, a lot of these babies will fly.

Seth Shulman's book Unlocking the Sky: Glenn Hammond Curtiss and

the Race to Invent the Airplane will be published in September.

|

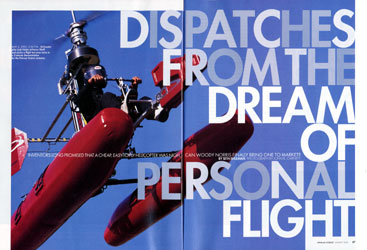

May 2, 2002, 2:56 p.m.: AirScooter

pilot Jack Nolan achieves liftoff and circles a flight test area twice in a

3-minute demonstration for the Popular Science cameras.

Photograph by John B. Carnett

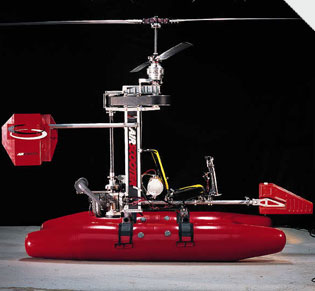

Easy does it: No fancy footwork

required: The AirScooter has footrests, not pedals; the exposed mechanics are

basic and sturdy.

Photograph by John B. Carnett

Easy does it: No

fancy footwork required: The AirScooter has footrests, not pedals; the

exposed mechanics are basic and sturdy.

Photograph by John B.

Carnett, Stylist: Vicky McGarry, Wardrobe by Bell Helmets, Flightsuits.com

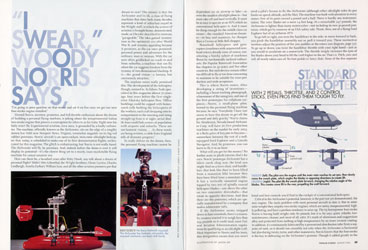

STANDARD HELICOPTER

With 2 pedals, throttle, and 2 control sticks, even pros find them tough to fly.

TAKEOFF (left): The pilot revs the engine until the main rotor reaches its set

rpm, then slowly raises the swash plate, which angles the blades in opposing

directions to create lift.

CRUISING (right): The pilot tilts the swash plate forward, changing the relative

angle of the blades. This creates more lift in the rear, propelling the craft

forward.

Illustration by Jason Lee

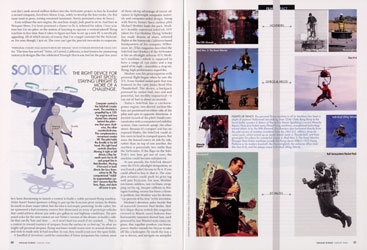

SOLOTREK

The right device for tight spots; staying upright is more of a challenge.

Computer control is the SoloTrek's trademark. The machine is propelled by a

120-hp engine and two ducted fans situated behind the pilot—one that spins

clockwise, the other counterclockwise. This complementary movement creates lift.

The pilot holds the throttle in his left hand. His right hand controls

direction: Moving it right or left directs a flap beneath each fan to tilt and

propel him in that direction. Moving it forward or back directs the fans

themselves to tilt. The computerized "stability augmentation system" ensures

that the fans, flaps, and ducts all move in sync.

Illustration by Jason Lee

AIRSCOOTER: Simplicity is the

mantra here. It's built to be cheap, light, reliable, and a cinch to fly.

Piloting the AirScooter is intuitive, thanks to a gimbal-based transmission. The

cab hangs from the rotors; to steer, the pilot merely points the handlebars in

the direction he wants to go. Water placed in the ballast tank balances the

engine's weight. The yaw paddles are fixed, but slant in tandem during a turn to

deflect the downdraft. The pontoons provide stability as well as safety.

Illustration by Jason Lee

|